Introduction: Why Circular Materials Matter

Sustainability is one of today’s biggest challenges. Governments, businesses, and consumers are all under pressure to cut emissions, reduce waste, and protect natural resources. The Apple circular economy shows how a company can lead the way—using recycled materials, smart design, and innovative supply chains to turn sustainability into action and set a global example.

Apple Inc., a global leader in consumer electronics, demonstrates how circular principles can be operationalized at scale. Beyond producing popular devices, Apple commands a complex supply chain spanning continents, giving it the power to influence suppliers, competitors, and regulators worldwide. When Apple commits to circular materials, it is not only reducing its footprint but also shaping market expectations.

This article examines Apple’s circular strategies, product implementations, challenges, and the broader implications for global sustainability. Drawing on real-world data, case studies, and comparative examples, we explore how Apple’s model can serve as a blueprint for other businesses and markets.

Understanding Circular Materials

Circular materials are designed to remain in production cycles rather than being discarded. They include recycled metals, bioplastics, and recovered rare earth elements. These materials reduce environmental impact, lower reliance on virgin resources, and cut carbon emissions.

Key Examples:

-

Recycled Aluminum: Maintains structural integrity indefinitely and reduces greenhouse gas emissions compared to virgin aluminum.

-

Rare Earth Elements (REEs): Extracted from old electronics to produce new devices, reducing the need for destructive mining.

-

Bioplastics: Sourced from renewable feedstocks, minimizing fossil fuel dependence.

-

Recycled Cobalt: Salvaged from used batteries to power new electronics.

So what? Circular materials are not just environmentally beneficial—they influence supply chain resilience, regulatory compliance, and brand positioning. Companies adopting them can reduce costs, secure scarce resources, and meet growing consumer expectations for sustainability.

Apple’s Environmental Commitments

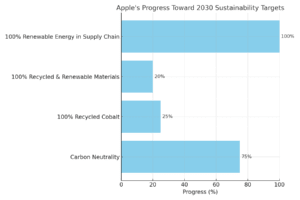

Apple has pledged to achieve carbon neutrality across its entire business and supply chain by 2030. This includes manufacturing, product usage, and end-of-life recycling.

SEE ALSO: The Complete Guide to Business Analysis: Strategies, Tools, and Case Studies for Smarter Growth

Milestones include:

-

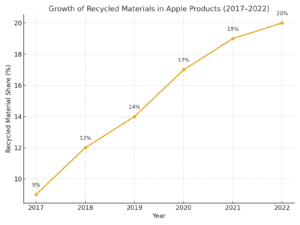

2022: 20% of materials in Apple products came from recycled sources (Apple Environmental Progress Report, 2022).

-

Recycled metals: 100% recycled tin solder, tungsten, and rare earth elements used in select product lines.

-

Renewable energy: All corporate operations, including stores and data centers, run on 100% renewable energy.

-

Batteries: By 2025, Apple aims to use 100% recycled cobalt in all devices.

So what? Apple’s commitments are significant not just in scale but in market signaling. Suppliers are incentivized to upgrade facilities, and competitors face pressure to match these standards, effectively creating an industry-wide ripple effect.

Key Circular Innovations

1. Recycled Aluminum in Devices

Apple’s MacBooks, iPads, and Apple Watches now feature 100% recycled aluminum enclosures.

-

Environmental impact: Eliminates millions of metric tons of greenhouse gas emissions associated with bauxite mining and smelting.

-

Market influence: After Apple’s adoption, multiple suppliers globally invested in recycling infrastructure to meet demand.

So what? The project proves that high-quality recycled metals can replace virgin materials without compromising durability or aesthetics. This sets a precedent for large-scale electronics manufacturing.

2. Daisy Robot: Closing the Loop

In 2018, Apple introduced Daisy, a robotic disassembly system capable of dismantling 23 iPhone models at 200 devices per hour. Daisy recovers cobalt, tungsten, aluminum, and rare earth elements.

-

Recovered resources: In 2022, Daisy enabled recovery of cobalt sufficient for thousands of iPhone batteries (Reuters, 2022).

-

Innovation significance: Robotics solves the efficiency challenge in circular electronics, reducing labor costs and enabling scalability.

So what? Daisy illustrates how automation can transform recycling from a niche effort to a global-scale practice, offering a model other electronics manufacturers can replicate.

3. Recycled Cobalt

Cobalt mining faces environmental and ethical scrutiny. Apple plans to source 100% of battery cobalt from recycled materials by 2025.

-

Current status: In 2022, 25% of cobalt came from recycled sources (Reuters, 2022).

-

Global implication: Reduces dependency on high-risk mining regions, mitigating both ecological damage and supply chain volatility.

So what? This move signals a shift toward responsible sourcing, with financial and reputational benefits for early adopters.

4. Rare Earth Element Recovery

Apple sources 100% of REEs in iPhone magnets from recycled sources.

-

Environmental benefit: Limits destructive mining and associated ecological harm.

-

Economic impact: Stabilizes supply of scarce materials critical to consumer electronics.

So what? Demonstrates that resource efficiency is not only environmentally responsible but also strategically critical in an increasingly competitive global market.

5. Supply Chain Partnerships

Apple collaborates with global partners, such as Elysis, a Canadian startup pioneering carbon-free aluminum smelting.

So what? These partnerships show that circular economies require collective action—corporations cannot implement systemic change in isolation.

Global Significance

-

Market Leader Effect: Apple’s size and influence compel suppliers and competitors to adopt circular practices.

-

Consumer Education: Visibility drives consumer expectations, normalizing sustainability as a purchase criterion.

-

Regulatory Influence: Alignment with initiatives like the EU Circular Economy Action Plan amplifies corporate impact on policy and market standards.

So what? Apple’s actions extend beyond corporate benefits—they catalyze structural shifts in both consumer behavior and regulatory frameworks.

Challenges and Criticisms

While Apple’s progress is notable, obstacles remain:

-

Scale limits: Daisy disassembles only a fraction of global devices annually.

-

Cost concerns: Circular practices often have higher upfront expenses than conventional sourcing.

-

Transparency issues: Critics call for more granular data on material sourcing.

-

Repairability: Restrictive policies can limit third-party recycling and reuse.

So what? These challenges highlight the complexity of global circular adoption and underscore the need for innovation, policy alignment, and industry-wide collaboration.

Lessons for Other Businesses

Apple’s approach provides actionable insights:

-

Design for Disassembly: Products must be engineered for easy recovery.

-

Invest in Innovation: Automation, AI, and robotics can scale recycling efforts.

-

Set Bold Targets: Ambitious deadlines create urgency and accountability.

-

Collaborate Widely: Cross-industry and policy partnerships amplify impact.

-

Educate Consumers: Awareness drives behavior change and market acceptance.

READ ALSO:

How Border Closure Weakens the Manufacturing Sector in Nigeria — A Deep Dive into the Hidden Costs

World Bank Warns of Nigeria’s Soaring Revenue Collection Costs — The Hidden Drain Behind the Numbers

Nigerian SMEs Compete for Relevance in the AfCFTA Era

So what? Businesses adopting these lessons can achieve both environmental and economic benefits, while future-proofing operations against regulatory and resource risks.

Complementary Global Examples

-

Patagonia: Implements take-back and resale programs, reducing textile waste.

-

Tesla: Developing large-scale battery recycling facilities.

-

IKEA: Targets full circularity by 2030 using renewable and recycled materials.

So what? These examples show circularity is not a niche strategy but a global business movement with measurable economic and ecological outcomes.

Conclusion: Toward a Circular Future

Apple’s circular economy initiatives illustrate that sustainable practices can be scalable, profitable, and strategically influential. From recycled aluminum and cobalt to robotic disassembly and supply chain partnerships, Apple offers a template for global business transformation.

The “so what?” is clear: as more corporations follow suit, the circular economy can shift from aspiration to mainstream reality—reducing waste, lowering carbon emissions, and stabilizing material supply chains worldwide. For businesses, adopting circular practices is not optional; it is increasingly central to competitiveness, reputation, and resilience.

Frequetly Ask Question (FAQ)

Q1: What exactly are circular materials?

A: Circular materials are resources designed to be reused or recycled instead of being thrown away. Think recycled aluminum, bioplastics, and rare earth elements recovered from old electronics. They help businesses cut waste, lower emissions, and rely less on virgin resources.

Q2: How does Apple use circular materials in its products?

A: Apple integrates recycled aluminum into MacBooks, iPads, and Apple Watches, recycles cobalt from used batteries, and recovers rare earth elements from old devices. The Daisy robot even dismantles iPhones to recover these valuable materials efficiently.

Q3: What are Apple’s big sustainability goals?

A: Apple plans to be completely carbon neutral across its entire supply chain and operations by 2030. This includes using 100% recycled materials in key products and running all stores, offices, and data centers on renewable energy.

Q4: Why should businesses care about circular materials?

A: Adopting circular materials isn’t just good for the planet—it strengthens supply chains, cuts costs, improves brand reputation, and ensures compliance with growing consumer and regulatory expectations for sustainability.

Q5: Can other companies follow Apple’s lead?

A: Absolutely. Businesses can learn from Apple by designing products for easy disassembly, investing in automation and recycling technologies, setting ambitious sustainability targets, collaborating with partners, and educating consumers about their green initiatives.

Q6: Which other global companies are leading in circular practices?

A: Patagonia runs take-back and resale programs, Tesla is building large-scale battery recycling, and IKEA aims for full circularity by 2030. These examples show circularity is becoming mainstream, not just a niche strategy.

Q7: What’s the bigger impact of Apple’s circular approach?

A: Beyond reducing waste and emissions, Apple influences suppliers, competitors, and even policymakers. Its actions set new industry standards, educate consumers, and show that sustainable practices can be profitable and scalable worldwide.

Share your perspective on corporate sustainability. How can businesses in your region adopt circular principles effectively? Join the discussion in the comment section below.

Leave a Reply